The MARK FOD 21 – 1440 Oil-Water Separator is the perfect system to separate oil from water in your compressed air system. It protects the environment and saves costs!

Oil-Water Separators

Once the condensate has been removed from the compressed air, it still needs to be cleaned in order to be in-line with local environmental legislations. For this process, oil-water separators are used.

Separating both substances (water and oil) results in rinsed water which can be discarded easily.

The limited amount of oil has to be discharged in a specialized disposal center.

Depending on the capacity of your compressed air system the FOD has 3 ranges, all very reliable, easy in use and extremely efficient.

Key benefits:

rinsed water which can be discarded easily and safely

easy operation

requires minimal installation and maintenance

meet environmental regulations and improve company image

excellent performance due to oleophilic and carbon fi lters

avoid high treatment costs

user friendly (e.g. maintenance indicator)

no electricity required

Oil – Water Separator

FOD 21 ÷ 1440

separable for hard, stable emulsions!

THE REASONS

Every process involving the compression, cooling and treatment of compressed air produces condensates that may contain more or less oil depending on the type of compressor.

As an example, if a compression system with a

refrigerant dryer with a capacity of 20 m3/min,

10 bar were to operate at 60% full load, two

shifts a day, for 220 days/year, at a room

temperature of 25 °C and 70% relative

humidity, its condensate production would be

about 39,000 litres/year.

Not only is it illegal to discharge condensates polluted with oil and/or hydrocarbons into sewage systems or the environment, but it also makes the already critical environmental situation worse.

It is well known that oil is a high pollutant. Even a small quantity can cover a vast water surface.

Collecting and disposing of these condensates is both difficult and extremely costly due to factors including:

– Local storage,

– Transportation to specialised centres for aftertreatment of specific waste,

– Maintenance of appropriate registers, where required.

On the basis of the above example, in the space of one year, we must:

– Manage the storage of 39,000 litres of industrial condensate;

– Organise its transportation to specialised disposal centres;

– Sustain the cost of aftertreatment and disposal, which, taking the average cost to be 0.10 euros/litre, would mean a cost of

3.900,00 euros.

Separating the oil from the condensate water right from the outset is undoubtedly less burdensome both in terms of management and general costs.

MARK has always prioritised environmental management, and has held UNI EN ISO 14001certification since 2001.

We offer:

FOD

– A simple solution to a big problem;

– An aid to help humans protect the environment..

The FOD oil/water separator is simple to install and use, and does not require electrical powering.

The oil is separated through a multistage filtration process.

The oil is absorbed by special absorbent substances inert to water which, once saturated, are removed and managed in

the same way as normal oil removal filter cartridges.

At the end of the process, the condensate can be discharged into the sewage system in compliance with prevailing local regulations.

TECHNOLOGY – PRINCIPLE – ENVIRONMENT

FOD is state-of-the-art technology for the treatment of condensates derived from compressed air.

FOD is a state-of-the-art multistage cascade filtration system for the

separation of oil from condensate water.

This innovative patented system is not affected by condensate

discharge under pressure.

The condensates can be channelled directly into the intake pipe without

any need for special collection manifolds.

The floating oil skimmer filters and the final active carbons are not

damaged by vibrations, jolts or sprays, and guarantee consistent high

long-term performance without problems of any kind.

Principle

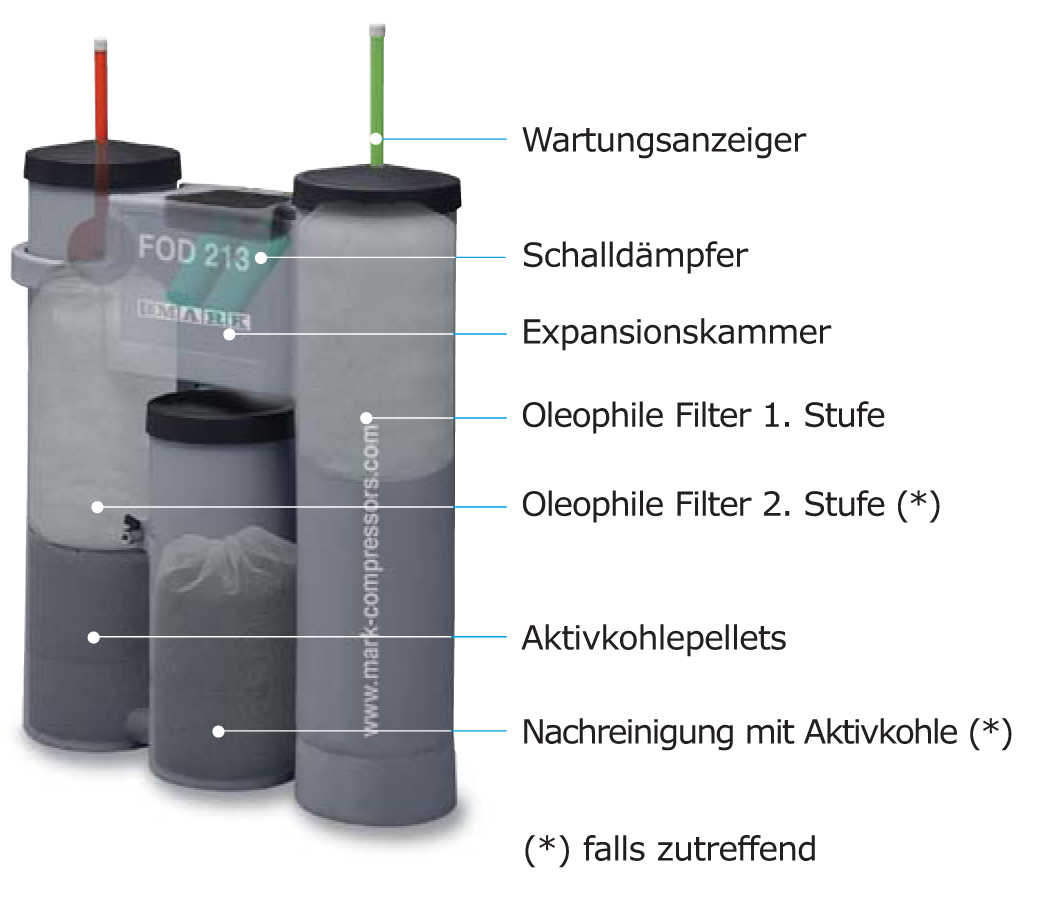

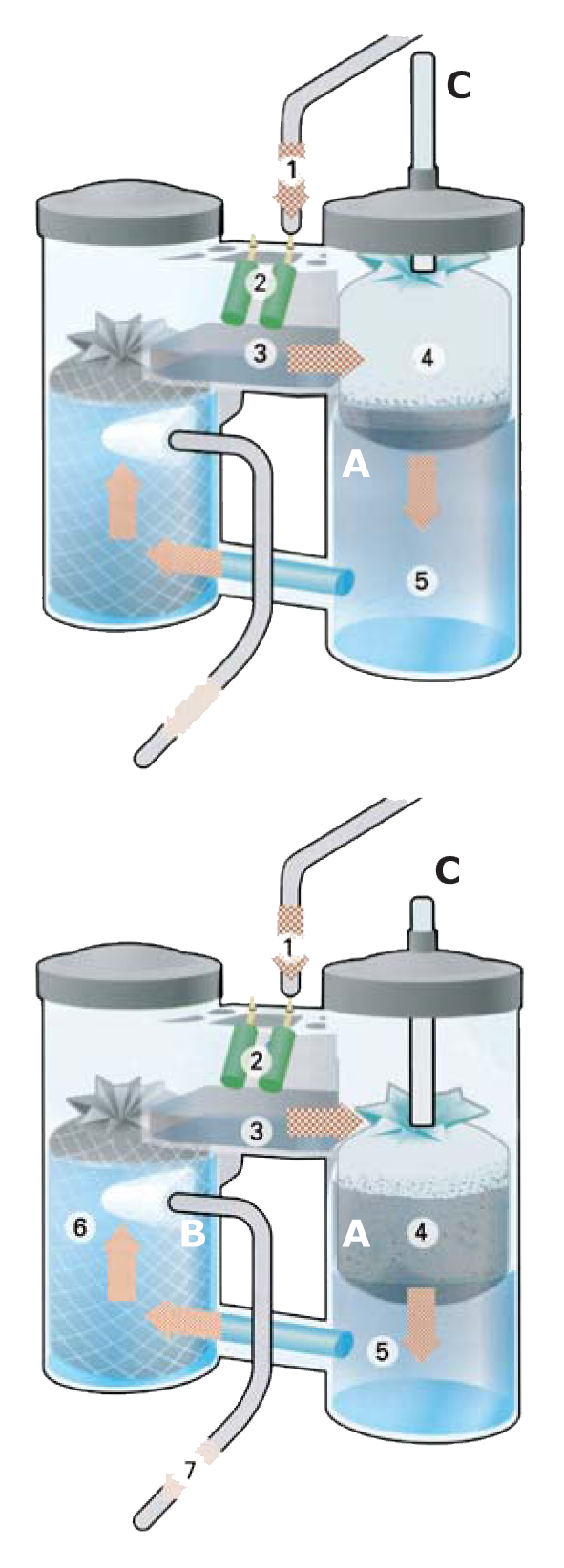

The condensate (1) passes through the silencer (2) into the

expansion chamber (3).

After this, it is channelled into tower A through the oil

skimmer-filter (4), which traps most of the oil but allows

the water to flow through (5).

The floating oil skimmer filter also absorbs the film of oil

that commonly forms on the surface.

As the filter slowly absorbs the oil, it begins to get heavy

and consequently sinks lower and lower into the liquid

triggering the maintenance indicator “C” to withdraw.

Once the filter is saturated it sinks completely.

The condensate then passes into tower B and through the

active carbon bed, still containing a small amount of oil (6).

Here the remaining oil particles are trapped, while the

condensate can be discharged containing hardly a trace of

oil residue (7).

Depending on the size of the machine, one or even two

sets of filters can be used (oil skimmer + active carbon)

• Oil separation by means of filtration, prevents the need for separation,

resulting in greater health safety and lower cleaning requirements.

• Higher and constant long-term performance regardless of the oil

concentration at intake.

• Great load capacity prevents condensate leakage due to any

unexpected increase in the intake flow.

• Simple and robust, easy to install, and no need for special settings.

• There is no need for oil recycling containers.

• Simple to maintain.

• Maintenance kits are available to suit all needs with oil residue recycling buckets.

OIL–WATER SEPARATOR

ÖWAMAT®

LEADERSHIP EXPERIENCE ENSURES

ÖWAMAT ® from BEKO are optimally matched to the operational requirements. In more than two decades and evolved and improved, they are now available, especially in the generation of the often imitated but never equaled scale of the industry.

Superior technology and function ÖWAMAT ® devices:

– System-specific sizes

– No energy cost

– National technical approval for all sizes

– No water permit necessary

– Low maintenance costs. Control only 1x per week

– Payback within a few months

– Depending on the size 90-125% more power

Vorteile

Benefits

+1: Double the performance

+2: Very easy handling by cartridge technology

+3: Double the service life of the filter units

+4: Pattern approval and without free oil separation

+5: Anytime simple retrofitting a heating

Please contact us for price quotation!